WHAT IS CERASLEEVE ?

CeraSleeve® is a patented paper coating technology that

minimizes waste, maximizes material recovery and conserves resources.

The key advantage of our ultra-thin and eco-friendly solution lies in its ability to replace conventional wet-strength and sizing agents with a sustainable material.

CeraSleeve® is completely free of plastic and can be applied to a wide range of products.

THE CHALLENGES

OF MANY PAPER PRODUCTS TODAY

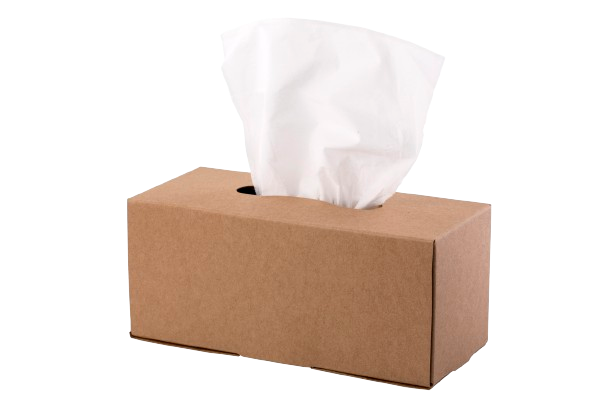

Paper is a highly sustainable and natural product. However, numerous paper products undergo functionalization to enhance their physical properties.

For instance, wet-strength papers like paper towels are treated with wet-strength agents, whereas water-resistant papers are often modified with sizing agents. These paper products share the following challenges:

Hardly recyclable

Today, wet-strength or water resistant paper products are hardly recyclable in conventional processes.

Made of fossil fuels

Most paper additives and coatings today consist of polymers made from fossil raw materials.

They are not bio-degradable and a source of microplastic.

Potential risk to our health

Side products from wet-strength and sizing agents can migrate from paper into food and are suspected to be harmful.

OUR SOLUTION

Imagine if we could enhance the sustainability of consumer products by harnessing the brilliance of nature.

This very question inspired us to pioneer a groundbreaking approach to crafting a functional additive for paper.

No detrimental chemicals, no harm to the environment and no health concerns.

Our technology is exceptionally clean and powerful.

100%

recyclable

CeraSleeve® coated paper can easily be recycled in conventional processes. In that way, valuable fibers re-enter the cycle and are recovered instead of being burnt.

0%

Microplastic

CeraSleeve® consists of silica, which is fully inorganic. Silica can be found in large quantities in nature and is neutral to the environment.

0%

Harmful substances

CeraSleeve® does not harm the environment or health. Silica is widely used in cosmetic, food, and pharmaceutical products.